Saturday, May 6 2017

My eldest grandson will soon be 11. Seems one of the in things these days are fidget spinners. I can make that. Maybe not as fancy as store bought, but I’m sure he’ll get at least 5 minutes of enjoyment out of the toy.

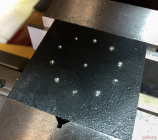

I cut out a 2" x 2" (plus) section from some 3/8" steel. I’m going for a 50 mm diameter with a skate bearing (22 mm OD) in the center. That leaves room for 10 8 mm holes to even things out.

hole pattern

holes

First try: I spot drilled the hole pattern using tables from Machinery’s Handbook adjusted for diameter. It looked OK so I drilled the holes. I do not have a DRO on my micro mill, only the dials. Somewhere along the line I messed up turning the dials. When I mounted the part to a mandrel I made using the center hole and put the mandrel in the lathe it became obvious that my center hole was no where near the center of the pattern.

2nd try

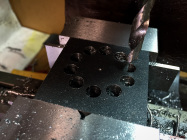

Second try: Cut another piece of 2" x 2" (plus) steel. Mark and drill the center. Mount to the mandrel and put it on the lathe. Turn down to the desired diameter. Move the piece to the 3 jaw chuck, face both sides, and bore the center to the desired size. Chamfer all edges. Now move the piece to the mill.

I used an edge finder on the internal 22 mm hole to determine the center and then used the tables from the handbook adjusted for diameter. The first 6 holes were fine but I could see when I went to spot drill the 7th hole that I’d goofed. No problem. I was able to go back to my center and re-position the mill table. Apparently I’d miss counted a rotation of the crank and was off by 0.050". It was very easy to see I was off on the circular part before I messed up.

Blued spinner

After drilling and deburring all 10 holes I used a counter-sink in a hand drill to slightly chamfer the holes. Some cold blueing was applied to give it darker look and hopefully inhibit corrosion. Lastly the bearing was inserted with a few drops of loctite super glue just to make sure is stays.

I may be able to salvage my first try. The hole pattern is not perfect, but OK for a childs toy. I’ll try to center the piece on the hole pattern in my 4-jaw chuck and bore a hole at center. I’ll make another mandrel to fit the hole once it is round. Then I can turn the outer edge. I hope.

Sunday, May 7 2017

It looks like I can save my first try. Unless I screw something else up.

Bored center

I put the piece in a 4-jaw chuck and aligned the pointer of my surface gauge with the outside edge of one of the holes. I went back and forth adjusting the jaws of the chuck and the pointer until the outer edge of all holes aligned with the pointer as I spun the chuck.

Once that was done I ignored the existing off center hole and bored a new hole to the desired 22 mm dimension for the bearing. It was an interrupted cut until the new hole subsumed the original hole.

Ready to turn mandrel to size

I put my collet chuck on the lathe and mounted my original mandrel inverted. I’ll turn down the larger diameter to match the 22 mm I bored in the spinner. Then I can mount the spinner and turn it down to the desired size. I’ll probably saw off some of the larger points, first. Much faster that way.

Monday, May 8 2017

Cut off some of the corners

tight fit on mandrel

Ready to turn

I cut off some of the corners and turned the mandrel down to size for a tight fit on the spinner. I wound up holding the mandrel in the 3-jaw chuck instead of the collet chuck. I had plenty of material to grab. I was turning down less than 3/8” to the 22 mm diameter needed to hold the part.

Turned, faced, and blued

The completed spinner

Done. It will be the back-up toy, stored for whenever the original is lost. I’m assuming that 11 year old boys still lose things. I did when at that age. Alas, I still do. With my luck I’ll forget where I put this back-up if the original is ever lost.